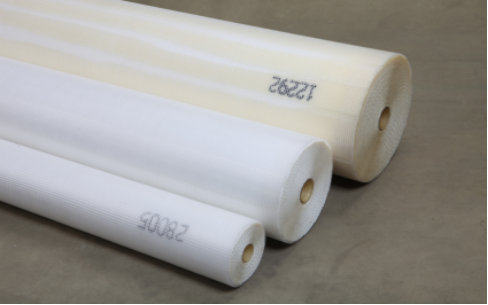

● Membrane Material: PA

● MWCO.: 100~300 Da

● PP/PE Non-woven fabric

● Advantages: High temperature resistance

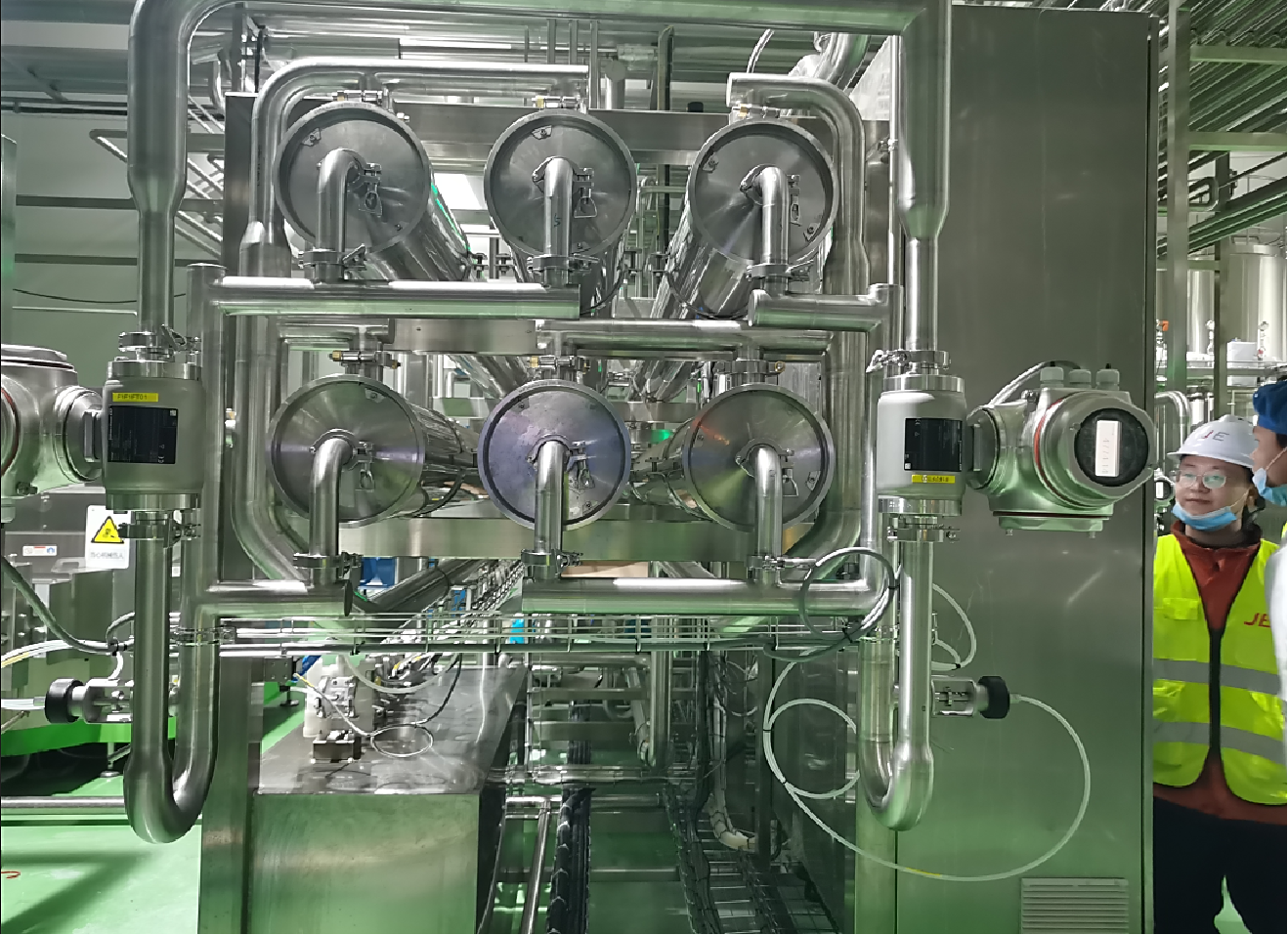

Our Dairy sanitary spiral membranes are exceptional at standardizing milk and concentrating and purifying proteins, lactose, and permeate. Available in a variety of pore sizes, our membranes provide a cleaner protein separation and increased throughput. These advanced crossflow filtration membranes combine innovative construction and optimized subcomponents to improve energy efficiencies, reduce operating costs, increase productivity, and decrease contamination risk. In the dairy processing industry, membrane separation technology is used to separate, and in some cases, purify an essential constituent of milk like fat, protein, lactose, minerals, etc. As each of these components have specific nutritional properties,fractionation of these components will enable pure ingredients to be produced that have the advantage of constant quality.

Nanofiltration is a RO process in which a more open membrane allows small monovalent ions such as sodium and chloride to pass. This means that NF combines concentration (like RO) and partial demineralisation. The NF process can be used for a wide range of applications in the dairy industry, e.g. demineralisation of whey, milk and permeate from UF of milk or whey

Advantages:

· Proven components and system design

· Proven membranes for NF dairy applications

· Optimised performance and long membrane lifetime

· In-line UF, NF, RO polisher

· High-quality engineering, standardised system

· Optimised utility consumptions

· Pre-assembled in our workshop

· Operator- and maintenance-friendly