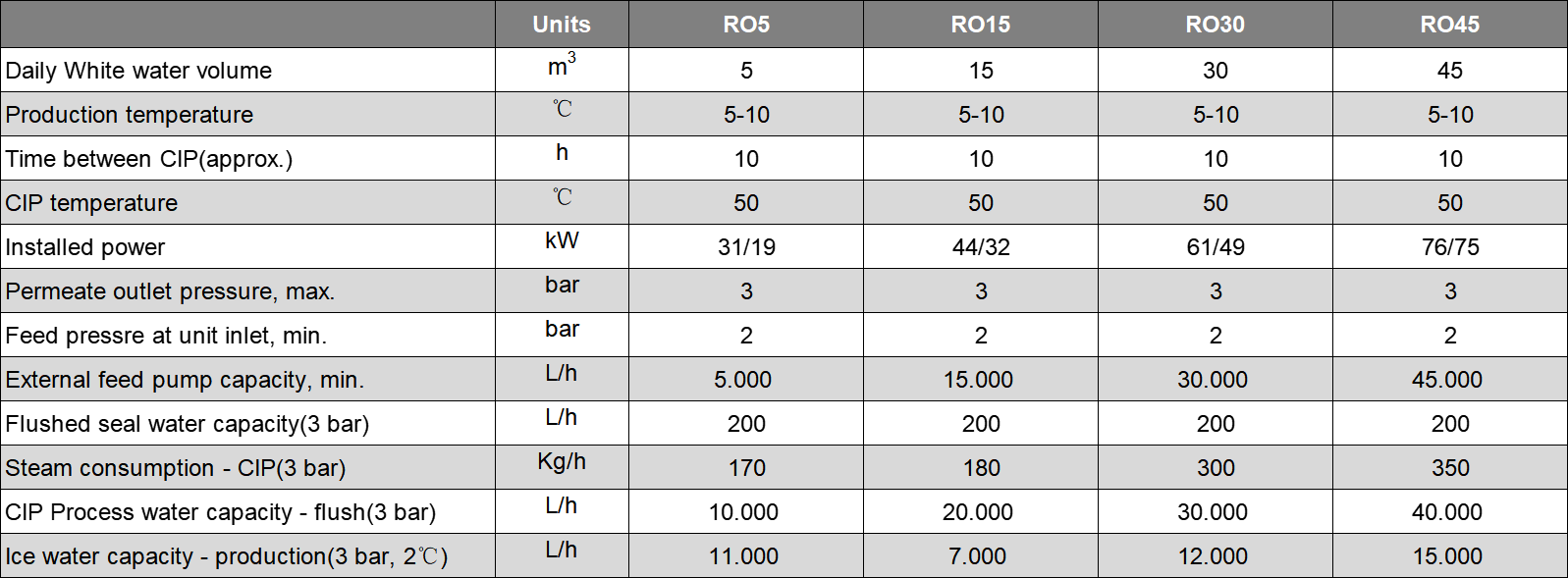

● Volume: 5/15/30/40m³

● Batch processing at 5-10°C

● Operating time: 10 hours between CIP

● All parts in contact with product made of stainless steel AISI 316L / DIN1.4404

The membrane filtration technology offers several possibilities for achieving more sustainable processes in the dairy industry - all of which also imply reductions in production costs. Our membrane technology offers cost-effective processing solutions, enabling dairies to reach their sustainability goals in both a simple and very cost-effective way.

The system is based on proven reverse osmosis (RO) technology which enables effective processing of collected white water by concentrating milk components back to their original compositions or higher depending on the use of the recovered milk.

Designed for recovery of milk and usable water from so called “white water” (mix of milk and water made at the first water flush of dairy equipment during CIP cleaning process).

System enables use of the recovered milk for cheese, yoghurt, ice cream and flavoured milk, but not for natural drinking milk. The water component (permeate) can be used immediately for CIP or polished using the same RO system to produce high quality soft water at very low COD level for use as process, boiler or cooling water and top up in CIP systems.

Capacity

Four standard sizes with nominal capacities of: 5, 15, 30 and 45 m³ of white water per day (batch operation), based on diluted whole milk and 10 hours production time at 5-10°C.