● Volume: 5/15/30/40m³

● Batch processing at 5-10°C

● Operating time: 10 hours between CIP

● All parts in contact with product made of stainless steel AISI 316L / DIN1.4404

The membrane filtration technology offers several possibilities for achieving more sustainable processes in the dairy industry - all of which also imply reductions in production costs. Our membrane technology offers cost-effective processing solutions, enabling dairies to reach their sustainability goals in both a simple and very cost-effective way.

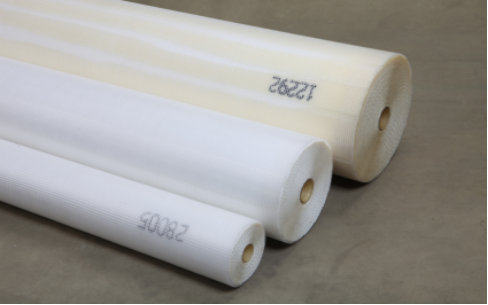

The system is based on proven Ultrafiltration (UF) technology which widely used in the dairy industry.Such as concentration of milk or whey,milk protein concentrate(MPC and MPI), cheese processing, and so on.

For milk and whey protein concentration

Ultrafiltration for concentration of milk or whey is widely used in the dairy industry. UF concentration is used as a concentration step

in the process of making different whey or milk powder products.

Also different fresh cultured cheeses like cream cheese, Feta

and Queso Fresco can be produced by UF concentration with a substantially higher yield

UF milk protein concentrate - MPC and MPI

Milk protein concentrate is produced by using ultrafiltration to concentrate skim milk. The result is a product with a high content of protein and a low content of lactose and ashes. MPC and MPI are made in various grades from MPC 50 to MPI 90 and are used in for instance processed cheeses and a wide range of other food applications

UF protein standardisation and concentration

By means of UF whole milk or skim milk is separated into

a protein rich fraction and a protein free fraction. By controlling the exact amount of protein in a certain amount of milk, the

protein content can be increased or decreased

UF cheese systems

UF is a well-established and proven technology for

a wide variety of fresh cultured cheeses.

The UF based cheese process is a continuous process with increased yield compared to traditional

cheese processing. The UF technology secures a

more homogenous product with stabilising effect

from the whey proteins. Furthermore, the process

gives the flexibility of producing different kinds of

cheeses on the same equipment